Why Jailhouse wine? Without being to either, I would imagine jail is an upgrade from prison, and while I made prison wine using just grape juice and bread yeast, I think that the folks who are in temporary custody might have access to better ingredients, like aging oak, specialty strains of yeast, and better juice blends.

Okay, it’s a gimmick. This is just an iteration of that previous wine I made, using similar but better ingredients.

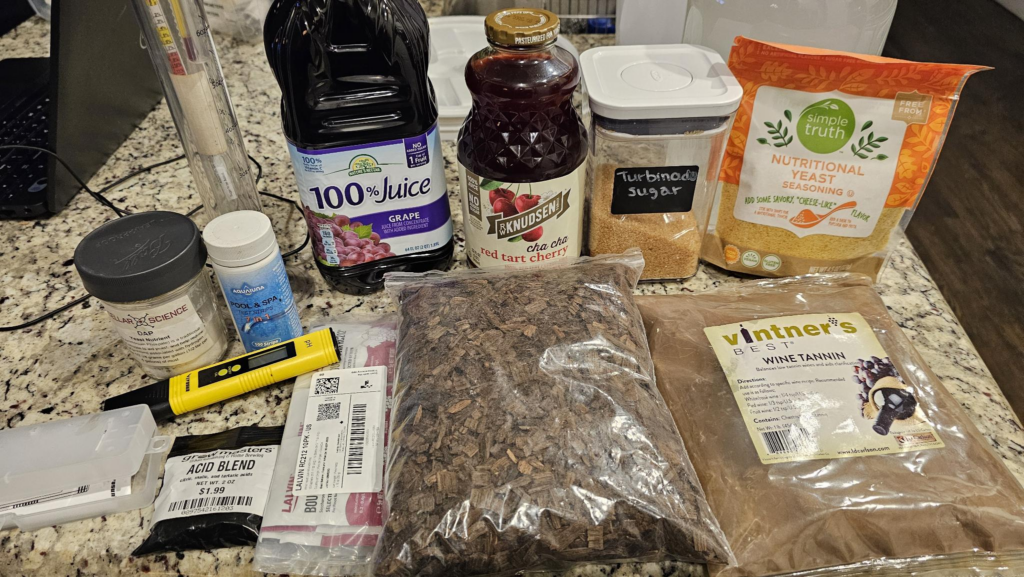

I’ve been talking to my good friend GPT recently and bouncing ideas off of it to formulate a recipe, plus a bit of my brewing background. Here’s what you’ll need:

Equipment

- 1-Gallon glass fermenter with lid and airlock

- Test jar and hydrometer for brewing ranges

- pH test strips or pH meter

- Brewing thermometer (or just one that can get wet)

Consumables

- 64oz of grape juice without preservatives (see the Prison Wine blog for more on that)

- 11oz of cherry juice without preservatives

- 1/4tsp Diammonium Phosphate (DAP)

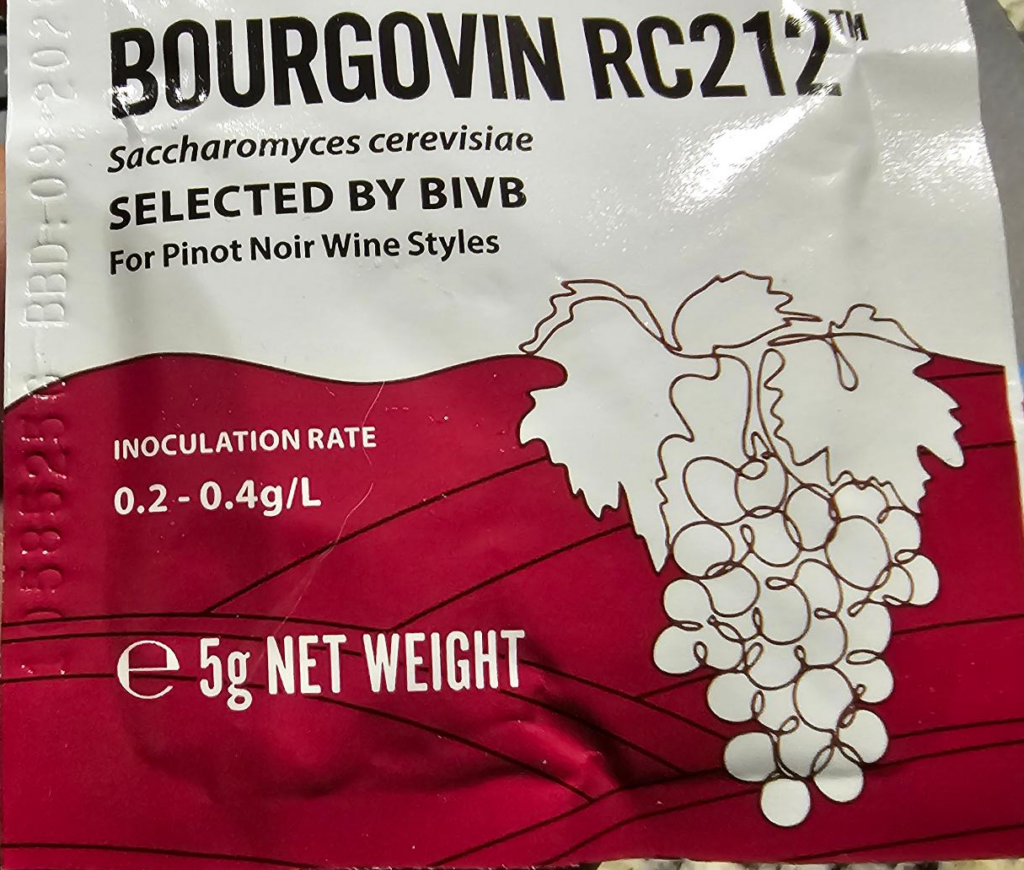

- 1/5 packet of Lalvin RC212 (Bourgovin RC212) Yeast (one packet is enough for about 5 gallons)

- 1/8tsp of Tannin powder — optional, I have a pound of it above, I needed 1/8tsp. I’ve never used it and I don’t know the right dosing rate, but this makes a little over 1/2 gallon and I believe this to be right. If you’re local to me and want to try this, I’ll just give you some.

- 11oz Turbinado Sugar, you can sub white table sugar or, better, corn sugar for less flavor impact

- Star San, mixed

Later Consumables

You won’t need these today, but worth ordering to have for when fermentation stops in a few days:

- Acid Blend (if needed, not sure yet)

- Nutritional Yeast (while I used a tiny bit of it, I have a strong feeling I should not have)

- Oak Chips — I went with American White Oak, Medium Toasted

Step 1: Be Clean

Yeast and bacteria are everywhere. You can toss a raisin in your must (the liquid we’re going to make today) and it will likely ferment into alcohol. Raisins and grapes have natural yeast on the outside, which is why grapes have that “dusty” look to the skin.

The reason we use commercial saccharomyces cerevisiae to produce wine, beer, and bread is that we have tuned the parameters of the yeast strains to produce different flavors, quantities of oils for mouthfeel and so on — it’s predictable. It also eats only some types of sugar. You can (and I have) fermented with brettanomyces bruxellensis, commonly called “brett”. It can create big issues when you think your beer is done fermenting, you bottle it at a higher specific gravity with some priming sugars, and then this other strain decides to ferment your beer dry and make bottle bombs.

To control fermentation: The most important thing you can do is ensure you clean your fermenters to remove any dust, dirt (and therefore yeast and bacteria) out of them. Rinse them several times to ensure there’s no soap that will touch your must, and then sanitize with mixed StarSan (don’t fear the bubbles).

I’ll let how to do that be an exercise for the reader, but the way I do it is I have a 5-gallon food safe bucket I keep it in, dip the entire fermenter, lid, airlock, test jar, hydrometer, thermometer, the tops of the juice jars, and any tools I plan to use (Turkey baster / wine thief, whisk, etc) and let them sit for a few minutes.

Step 2: Make

Mix all of the consumables listed above in the gallon fermenter, except star san and Lalvin yeast. You can do what I did and add 1/8tsp of nutritional yeast as well but I think I would skip it (to be determined when I do the next step).

Use a sanitized whisk and dissolve the sugar, if you have another sanitized vessel, I would rapidly dump it from one into the other. Oxygen ruins brews is absolutely true once fermentation has started. Before, however, oxygen is wonderful and you want as much dissolved into the must solution as possible for a vigorous and clean fermentation.

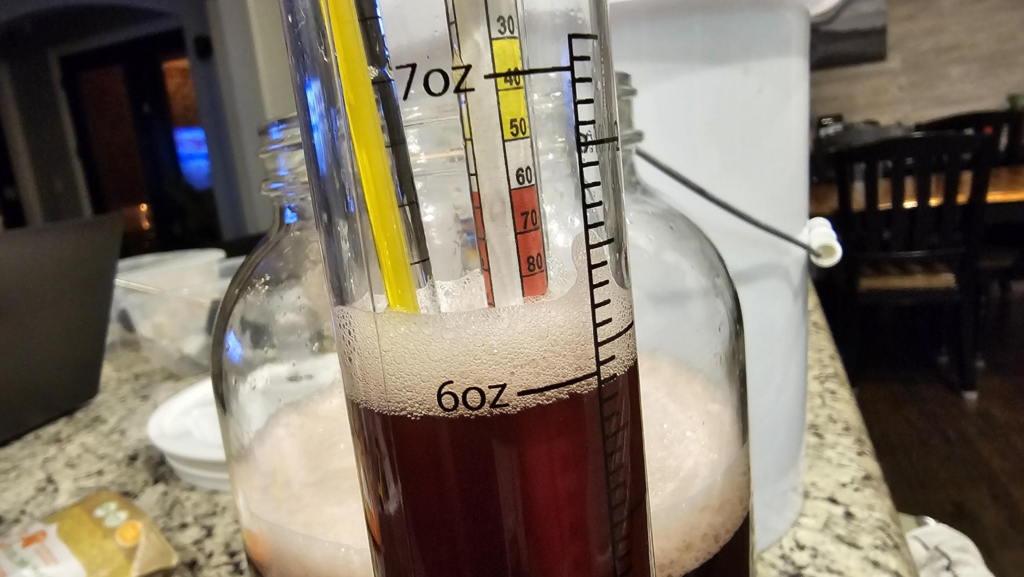

Step 3: Measure & Pitch

I measured my SG (starting gravity) at 1.100 @ 62F. Remember that you have to correct your gravity readings to the current temperature of the sample. In my case, no correction was needed. Pay attention to the meniscus of the liquid throwing false readings — in my case, since I shook the shit out of the must, I have to contend with a ton of foam and estimate the 1.100 value.

This means that if it ferments to typical cabernet sauvignon FG (final gravity) of 0.995, I should be getting around a 14% ABV wine:

(1.100-0.995)*131.25 = 13.78%

Sometimes you’ll see pitch rate, but I think inoculation rate sounds pretty cool too. If we’re going to get really specific, we’re making 75oz of wine, so let’s do that math:

75oz out of 128oz in a gallon, 3800mL in a gallon

(75/128)*3800mL = 2,226.5625 total liters produced, divide that by 1,000 to get liters and multiple by the target rate.

Aiming for the median inoculation rate of 0.3g/L, we would need 0.66796875g of dry yeast.

STILL HERE LOL: Yeah, adding too much yeast won’t hurt. One packet is for 5 gallons. Haphazardly dump some in ~1/5 of the packet and save the rest for later. This part doesn’t really matter.

The yeast does want you to rehydrate before using it, but I frankly didn’t feel like doing it this time around and just pitched it. This has never caused a problem but in theory, rehydrating it can minimize off flavors.

Step 4: Wait

Slap the lid and filled up airlock on the top and put this in a dark place. If you can keep the temp around 70ish degrees, perfect. You can check on it on occasion, it should offgas a good smell. In about a week, check it again and see if it is still bubbling. If it is, we’ll want to check the FG. More on that when I reach the next step!

Leave a Reply